id

overview

Onesait Utilities Asset Performance Management (APM)

Asset Performance Management (APM) improves asset reliability, availability and reduces operation and maintenance (O&M) costs.

id

asset-health

APM is a comprehensive and modular solution to monitor assets and facilities, in utilities and asset intensive organizations.

It integrates the whole performance of the installation on a common and unified vision, from asset to fleet level, covering both health and performance perspectives.

Onesait APM for T&D is made up of two modules: Predictive Monitoring and Asset Health.

id

capabilities

Predictive Analytics

- Failure Detection

- Diagnostics

- Alert Management

- Machine Learning Algorithms

- Maintenance Support

Asset Health

- Maintenance prioritization ranking

- Reduced cost and risk

- Wide application range

- Remaining Useful Life

- Based on internal utility data or international standards

Cloud-Based Solution

- Scalability

- Cybersecurity

- Modularity

- Platform independence

id

monitoring

APM Predictive Monitoring

Advanced Condition Monitoring

Leverages existing instruments

- No additional sensors required

- Monitoring is based on existing Instruments

Machine Learning

- Machine learning algorithms

- Multivariable analysis

- Empirical models trained with historical data

Versatile

- Applicable to any equipment, model, and manufacturer

- Customizable models

Early warning

- O&M Cost Savings

- Highly secure and reliable

- Customizable alert rules

Any expected process data detected

- Detect deviations from expected data

- Real-time data is compared to model predictions

Adding value to traditional maintenance system

- Complimentary to other maintenance systems

- Consistent with other monitoring techniques

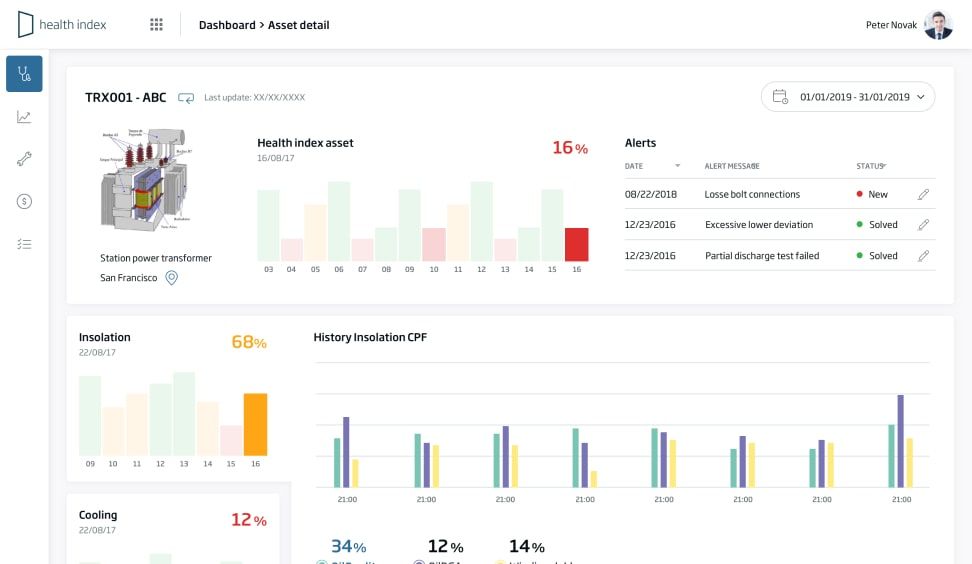

APM Asset Health

Assets Health Index calculation allows optimizing Life Cycle Cost (LCC) by redefining maintenance plans and prioritizing investment decisions

Health Index Analysis

- Based on equipment type and available data

- Considers Maintenance, Inspection and Operations data

- Customizable models

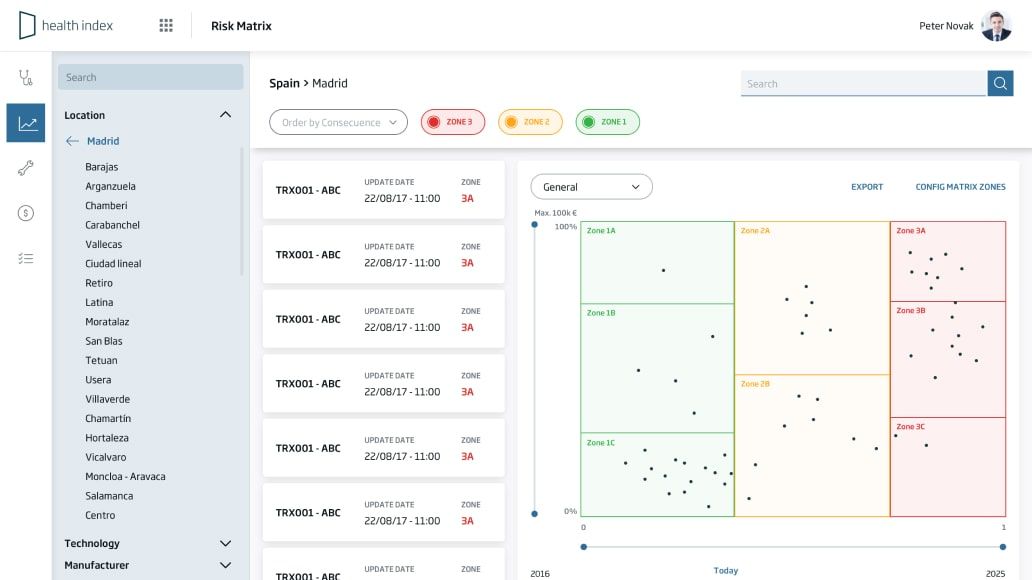

Risk Matrix

- Definition of failure modes

- Criticality analysis based on failure effects and probability

- Integration of historical data of maintenance

Maintenance Optimization

- Based on health index and failure modes

- Maintenance resources are allocated according to a rational prioritization

Life Cycle Cost (LCC)

- Remaining life can be determined based on Health Index

- Allows taking and prioritizing decisions regarding equipment replacement